Neuigkeiten

Designflexibilität für alle Ihre Anwendungsideen

SUYIN Produktübersicht Download

Vollflächige oder punktuelle Kontaktierung mit Zinn, Gold, Silber oder PdNi

Design der Steckverbinderverpackung passend zu Ihrem automatisierten Leiterplattenbestückungsprozess

Material- und platzsparendes Design

Flexibilität bei der Werkzeugausstattung und Anpassung der Produktionslinie mit austauschbaren Werkzeugteilen

Verschiedene Gehäusefarben und Codierungen

Verschiedene Leiterplattenmontagetechnologien wie Press-Fit, SMT, THT, THR (PIP)

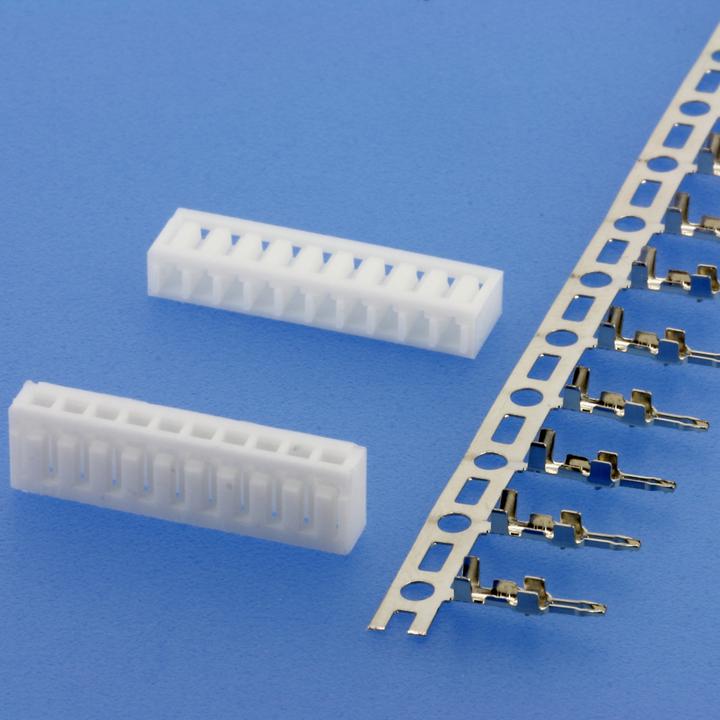

Hülsen werden an elektrische Leitungen gecrimpt, hauptsächlich Einzellitzen und Kabelbäume. Dabei wird das Kabel oder der Draht in die Hülse eingepresst.

Ein Bereich, in dem diese Technik bevorzugt wird, ist die Automobilindustrie. Die speziellen Werkzeuge sind vergleichsweise kostenintensiv, aber der Prozess lässt sich gut automatisieren.

Das Entscheidende beim Crimp-Prozess ist das ausreichende Verformen für die Verbindung, ohne das Material zu stauchen oder zu beschädigen. Die Qualität lässt sich dabei schon oft optisch gut beurteilen. Der ausgeübte Druck muss konstant bleiben, damit alle verarbeiteten Verbindungen den gleichen elektrischen Widerstand aufweisen.

Je kleiner das Rastermaß der Steckverbinder, desto größer ist die AWG-Zahl (Applicable Wire Gauge). Je kleiner aber der Aderquerschnitt, desto dicker ist das Kabel und desto höher ist die Strombelastbarkeit.

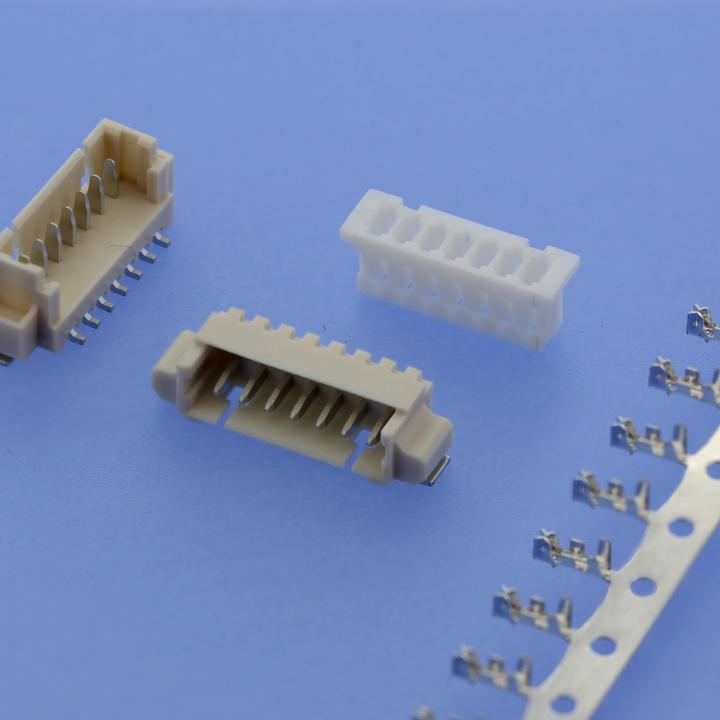

Die Crimp-Rast-Stift- & Buchsenleisten der Serie 5635 (RM 1,25) und der Serie 569 (RM 1,50mm) haben einen AWG-Bereich von 32-28. Beide Serien enthalten Gehäuse undBuchsenleisten mit verzinnten Kontakten. Die Isolierkörper sind entsprechend UL904 V-0 aus Thermoplast, der Nennstrom ist mit 1 A angegeben, der Temperaturbereich von -25° bis +85°.

Die Serie 569 ist gerade und 1-reihig und wird im THR-Verfahren verarbeitet. Die Serie 5635 ist als stehende und liegende SMT-Variante erhältlich und wird im Tape & Reel geliefert, bei der stehenden Variante mit Pick&Place-Pads.

Muster und Datenblätter sind auf Anfrage erhältlich.

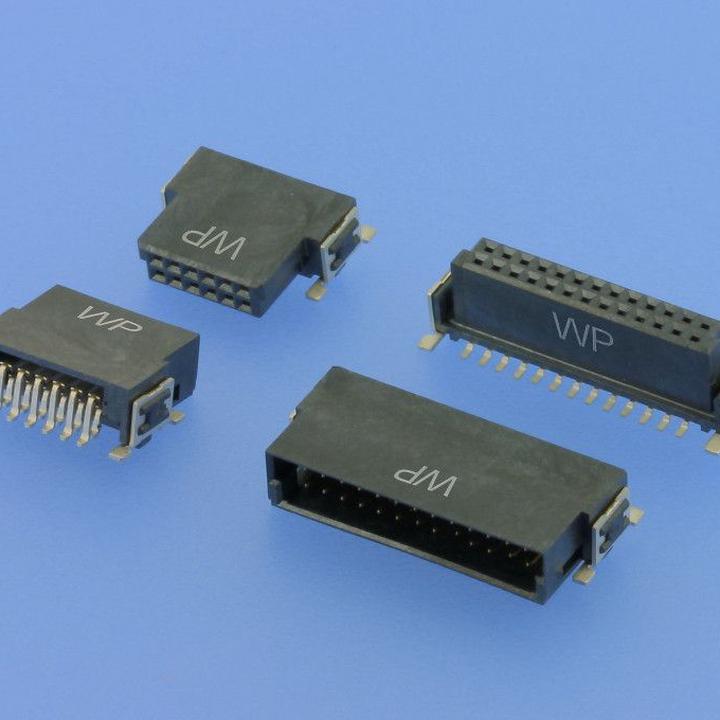

Zuverlässig und robust sollen Steckverbinder sein; die Verarbeitung schnell und kostenschonend.

Diese Ansprüche erfüllen THR-Bauteile (Through Hole Reflow), die – zusammen mit SMT-Steckverbindern – in einem einzigen Reflow-Lötvorgang verlötet werden können.

Somit entfallen die für das Wellen- oder Selektivlöten notwendigen Anlagen und Prozesse.

Eine Kombination aus den bewährten SMT- und THT-Verfahren

Das THR-Löten verbindet die Vorteile von SMT (Surface Mount Technology) und THT (Through Hole Technology) in einem Verfahren und gewinnt durch die bessere mechanische Belastbarkeit immer mehr an Bedeutung. Die Bauteile kontaktieren durch die Leiterplatte und werden in die Lötpaste im Bohrloch gedrückt, weswegen die Methode auch „Pin in Paste“ genannt wird.

Temperaturbeständig und automatisch zu Bestücken

W+P bietet ein breites Portfolio an THR-fähigen Produkten im Bereich Stift- und Buchsenleisten, Präzisions-Buchsenleisten sowie Wannensteckverbindern an. Da beim Reflow-Prozess hohe Temperaturen entstehen, bestehen die Isolierkörper aus temperaturbeständigem Kunststoff nach UL94 V-0 und halten von 20 bis 40 Sekunden bis zu 260° stand, angelehnt an IPC/JEDEC J-STD-020C. Auf der zur Platine ausgerichteten Seite sind die Gehäuse mit Abstandshaltern ausgestattet, damit die Wärme im Reflow-Ofen optimal zu den Kontakten gelangen kann.

Die Stiftlängen sind an die unterschiedlichen Leiterplatten-Stärken anpassbar und die Höhe der Bauteile sind mit den meisten Bestückungsautomaten verarbeitbar. Für die vollautomatische Bestückung werden die Steckverbinder noch mit Pick&Place-Pads ausgestattet und können dann in Tape&Reel oder Tubes geliefert werden.

Muster von THR-Steckverbindern sind auf Anfrage kostenlos erhältlich.

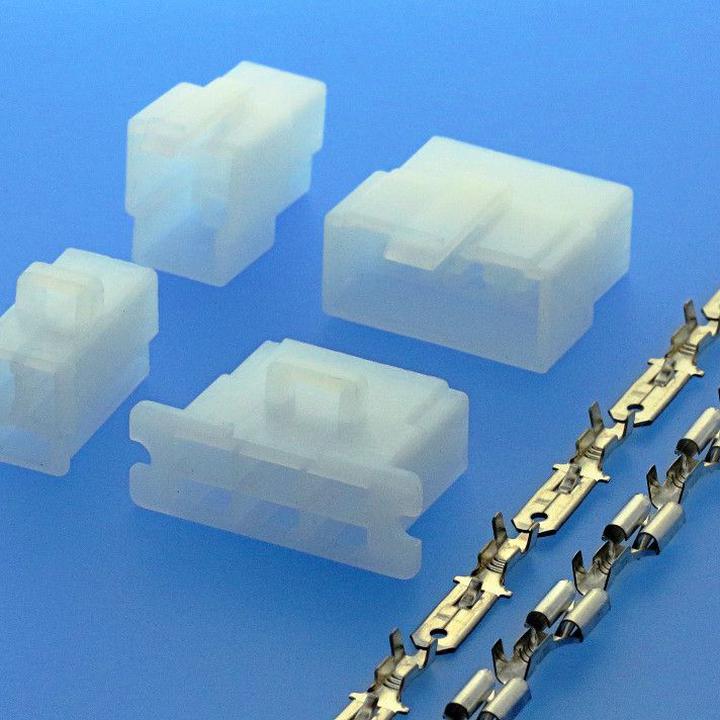

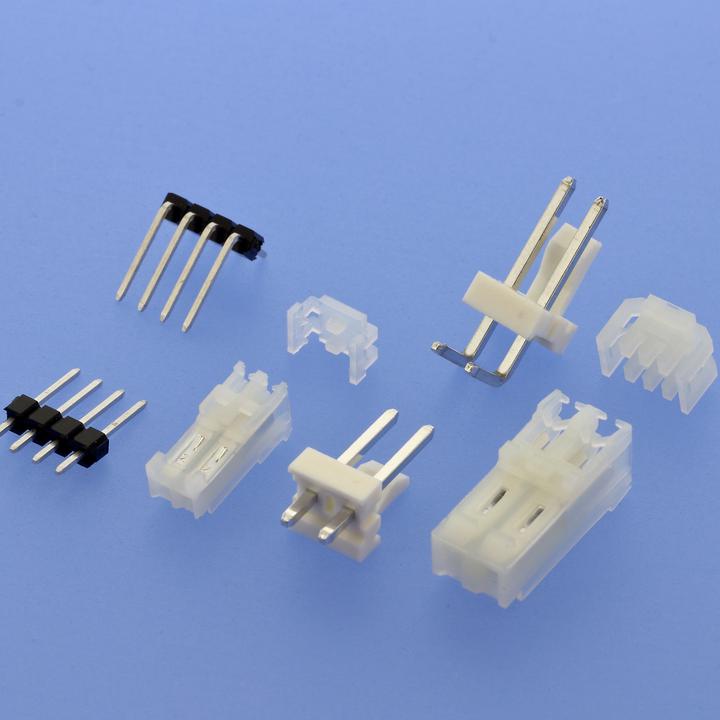

Wire-to-Board-(W-t-B) Anschlüsse haben diewesentliche Funktion, eine Strom-und Signalversorgung zwischen Kabel und Leiterplatte herzustellen.

Sie werden wegen ihrer hohen mechanischen Stabilität in derIndustrieelektronik, Stromversorgung oderBeleuchtung eingesetzt.

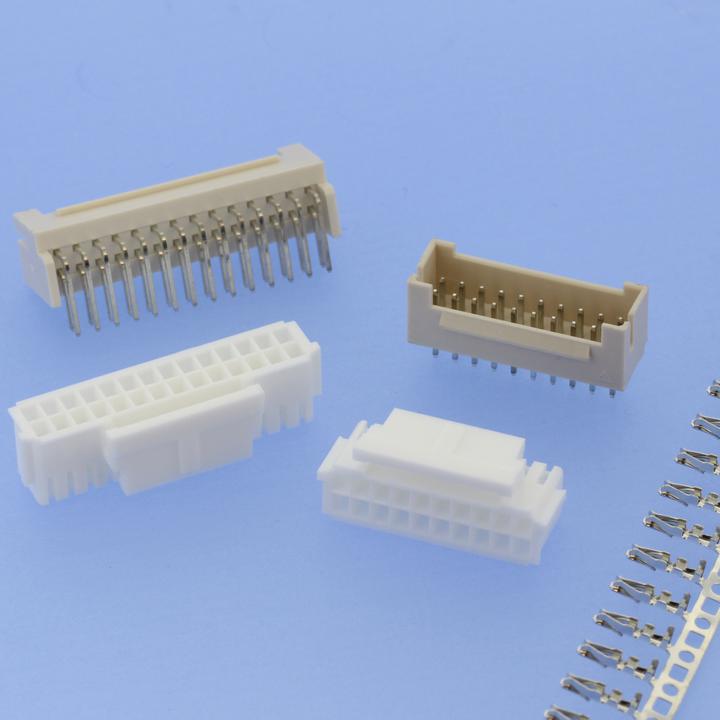

Die W-t-B Serie 548 von W+P erweitert als neues Crimp-Rast Element das Angebot mit einem kleinen Rastermaß von 2,0mm. Sie umfasst Buchsengehäuse (zweireihig) und Crimp-Kontakte sowie Stiftleisten in gerader und gewinkelter Bauform.

Integrierter Verpolschutz

Die Serie bietet als zusätzliche Sicherheit eine Gehäuseverriegelung. Dieses mechanisch kodierte Gehäusedesign verhindert versehentliches Lösen und dient gleichzeitig als Verpolschutz.

Die Vierkantstifte haben eine Kupferlegierung und sind zusätzlich verzinnt. Die Crimp-Kontakte sindausgelegt für einen AWG-Bereich von 28 bis 22, die Höhe des Nennstroms ist mit 3 A angegeben. Die Serie ist in den Polzahlen von 04 bis 40 lieferbar.

Die Isolierkörper bestehen gemäß UL94 V-0 aus Thermoplast, der Temperaturbereich von –25°C bis +85°C gewährleistet eine sichere Funktion.

Stiftleistenund Buchsen der Serie 548 sind als Schüttgut verfügbar, die Crimp-Kontakte werden als Tape&Reel geliefert.

Muster und Datenblätter sind auf Anfrage erhältlich.

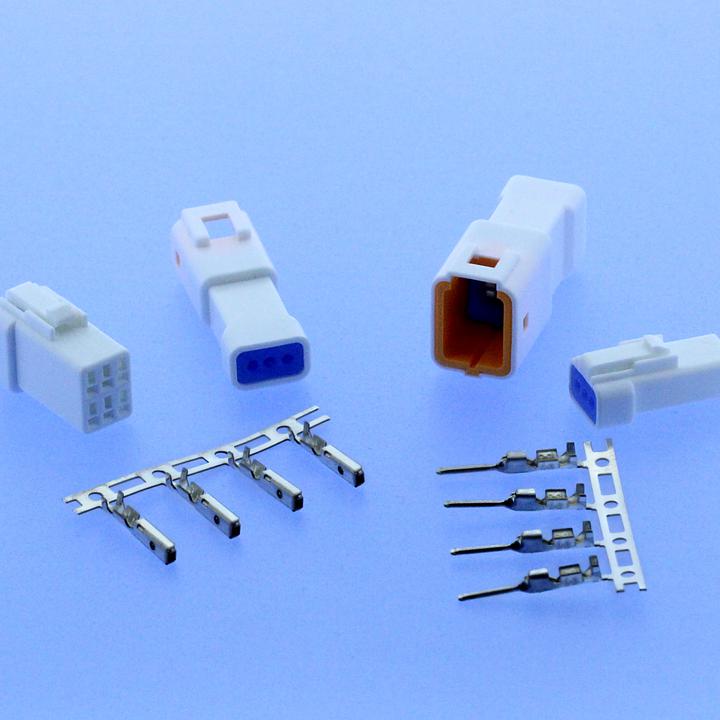

Sie sind platzsparend, wasserdicht und erfüllen die Schutzart IP67 – die neuen Wire-to-Wire Steckverbindersysteme von W+P: Die Serie W521 besteht aus Buchsen-, Stiftgehäusen und Crimp-Kontakten im Raster 2,0mm.

Als Kabelkonfektion ergänzt die Serie WA521 das Waterproof-Programm gemäß der Norm IEC60529.

Ein Silikonring übernimmt die normgerechte Aufgabe und schützt sicher vor Staub und Spritzwasser. Bei den ein- und zweireihigen Steckverbindern sind maximal acht Kontakte möglich, diese bestehen aus einer verzinnten Kupferlegierung. Bei einem Außendurchmesser von 1,4mm bis 1,7mm liegt der Aderquerschnitt bei AWG 26-22, der Nennstrom beträgt bis zu 4 A (bei AWG 22).

Sichere Verbindung durch Rastfunktion

Thermischen Belastungen halten die Gehäuse dank hochtemperaturbeständigem Kunststoff (UL 94 V-0) stand, der Temperaturbereich reicht von -55 °C bis +85 °C. Durch die Rastfunktion am Gehäuse ist eine komfortable, wasserdichte und sichere Verbindung gewährleistet, die jederzeit lösbar ist.

Bei der fertigen Kabelkonfektion (Serie WA521) ist die Litzenfarbe schwarz, weitere Farbtöne sind auf Anfrage möglich. Im Datenblatt sind die unterschiedlichen Kabel-typen mit Anschluss-Alternativen detailliert erklärt. Kabellängen variieren von 0,5m bis 2,0m – auch hier sind auf Wunsch zusätzliche Längen lieferbar.

Eingesetzt werden die Kabel-zu-Kabel-Verbinder bei rauen Bedingungen mit hoher Luftfeuchtigkeit, beispielsweise im Außenbereich (Beleuchtung) oder in Pedelecs.

Muster und Datenblätter sind auf Anfrage erhältlich.

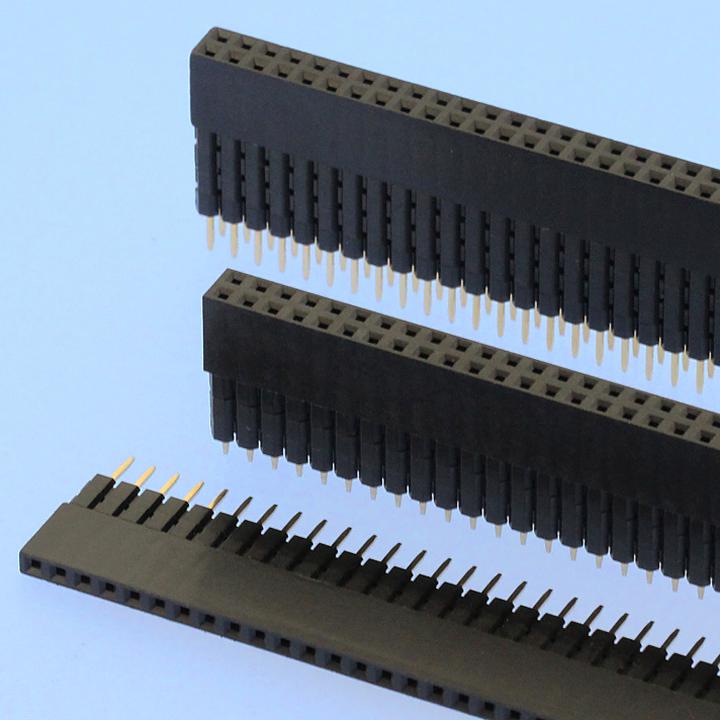

Um das Gesamtdesign in Elektronikanwendungen so kompakt wie möglich zu halten, werden Leiterplatten gestapelt.

Auch Steckverbinder helfen dabei, Platz zu sparen: Durch den Einsatz von Langprofil-Buchsenleisten wird ein zusätzliches Bauteil überflüssig. Zudem schützen diese die Kontakte vor Berührung, überbrücken unterschiedliche Höhen und sorgen für zusätzlichen Raum zwischen den Platinen.

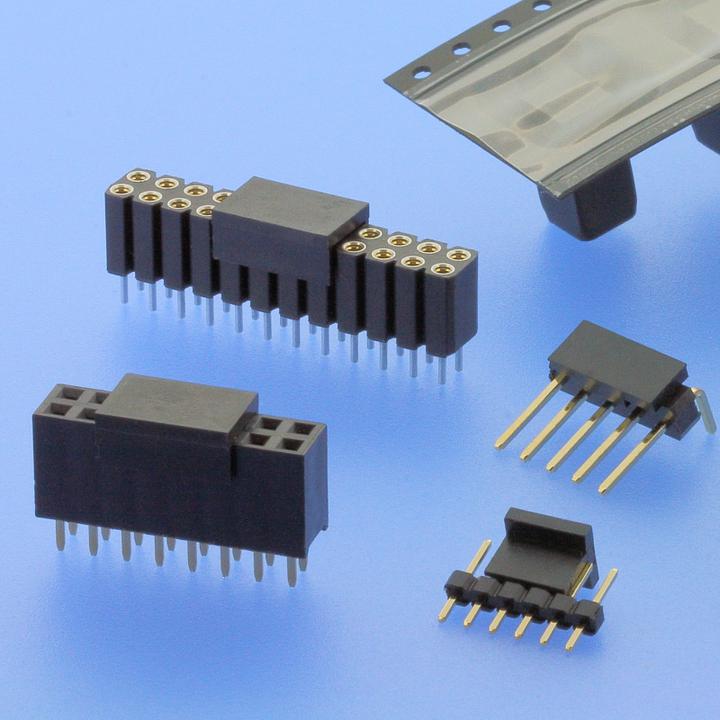

W+Ps Serie 626 bietet fünf verschiedene Typen mit Bauhöhen von 11 bis 21mm an.

Die Buchsenleisten sind im Raster 2,54mm als Einlöt-Version erhältlich.

02 bis zu 80 Kontakte möglich

Einreihig sind sie mit 02 bis 40 Kontakten und zweireihig mit 04 bis 80 Kontakten ausgestattet.

Als Kontaktmaterial steht eine Kupferlegierung zur Verfügung, die Kontaktfläche ist vergoldet über einer Nickelsperrschicht. Ausgelegt sind sie für einen Nennstrom von 3A.

Der Isolierkörper besteht aus thermoplastischem Kunststoff gemäß UL94 V-0. Eine sichere Funktion ist in einem Temperaturbereich von -40° bis +105°C gegeben.

Interessant ist ihr Einsatz im industriellen Bereich überall dort, wo Boards gestapelt und auch differente Höhen überbrückt werden müssen.

Muster und Datenblätter sind auf Anfrage erhältlich.

Attribute wie stabil, störungsfrei, sicher, schnell und verlustarm beschreiben am besten die Vorteile kabelgebundener Netzwerkverbindungen. Sie sind in Gebäuden, im privaten Umfeld oder im Büro unverzichtbar.

W+P erweitert mit der Serie 660 das Sortiment an vorkonfektionierten Netzwerkkabeln mit einer umfangreichen Auswahl an Ausführungen und Längen, auf Wunsch in verschiedenen Farben. So können lange Übertragungswege verlustarm überwunden werden.

Kabelverbindungen über große Distanzen

Unterschiedliche Kabeltypen (rund, flach) sind beidseitig mit 8-poligen RJ45 Verbindern versehen, die Kabelführung erfolgt gerade. Vor Beschädigung schützen PVC-Umspritzungen, welche als Zugentlastung mit integriertem Rasthebelschutz dienen.

Abhängig von der Ausführung sind Kabellängen bis zu 50m erhältlich. Geschirmte Varianten schützen weitestgehend vor Störquellen. Kabelquerschnitte können im Bereich AWG 32 bis 24 gewählt werden, weitere auf Anfrage.

Um leichter differenzieren und zuordnen zu können, gibt es sieben Mantelfarben, als Standard steht Grau zur Verfügung. Die Umspritzungen sind farblich entsprechend angepasst. Das Material besteht aus PVC, als Option halogenfrei (LSZH: Low Smoke Zero Halogen).

Anwendung entscheidet über Kategorie

W+P`s Ethernetkabel unterteilen sich in die Leistungsklassen Cat 5e, 6 und 6A. Cat 5e Kabel sind bewährte Verbindungen mit Frequenzen bis 100 MHz, bei 1 GBit/s. Deutlich leistungsfähiger sind die höheren Klassen: Cat 6 bietet Signalraten von maximal 250 MHz und einer Geschwindigkeit bis zu 1 GBit/s. Bei der nächsten Klasse Cat 6A sind es 500 MHz und bis zu 10 GBit/s. Die höheren Klassen sind abwärtskompatibel.

Standardmäßig sind die Kontaktflächen mit einer Oberflächenvergoldung von 1,27µm versehen. Das Material der Litzen ist aus Reinkupfer, die Spannungsfestigkeit beträgt 300 V AC.

Detaillierte Informationen zu Kabeldurchmesser, Kabelform, Biegeradius etc. liefert das Datenblatt.

Vielfältige Applikationen möglich

Einsatzgebiete sind alle Anwendungen rund um Netzwerkverbindungen – zu finden in Gebäuden und Kommunikationstechnik im Privaten sowie Office-Bereich.

Weitere Netzwerk-Spezifikationen und Farben sind auf Anfrage erhältlich.

Die Serie 660 ergänzt das schon vorhandene Angebot der RJ45 Kabelkonfektionen von W+P, zu dem auch die Serie WA610 als wasserdichte Alternative gehört.

Muster und Datenblätter sind auf Anfrage erhältlich.

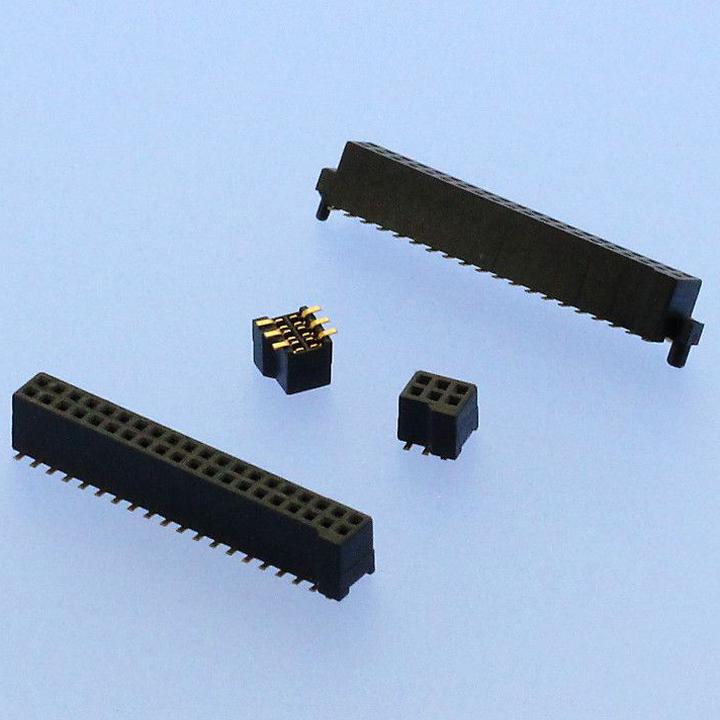

Leiterplatten auf engstem Raum zu verbinden ist eine Herausforderung in Elektronikanwendungen. Hierfür werden Steckverbinder in kleinen Rastermaßen und niedrigen Bauhöhen gebraucht.

Genau über diese Eigenschaften verfügt die neue SMT-Buchsenleisten-Serie 6067. Zusätzlich ist sie von oben steckbar, mit einem Rastermaß von 1,27mm. Die beiden wählbaren Bauhöhen sind mit 3,60mm und 4,50mm angegeben.

Stecksicherheit

Die zweireihigen, vertikal ausgerichteten Verbinder bieten eine enorme Bandbreite von 06 bis 100 Kontakten. Die Kontaktoberfläche ist vergoldet, der Durchgangswiderstand beträgt weniger als 20 m, mit einem Nennstrom 1 A pro Kontakt.

Wahlweise erhältliche Positionierhilfen erleichtern die Ausrichtung auf eine definierte Stelle auf der Leiterplatte. Um fehlerhaftes Stecken zu verhindern, geben optionale Kodiernasen Verpolsicherheit.

Passende Wannenstiftleisten komplettieren die Bauteile: Die SMT-Serien 6110 und 6111 sind ebenfalls als stehende Varianten verfügbar. Alle übrigen Stiftleisten im Raster 1,27mm sind gleichermaßen kompatibel.

Automatisierte Fertigung

Verpackungsangebote in Stangen und auf Rollen (Tape&Reel), stellen einen automatisierten Prozessablauf im Reflow-Verfahren sicher. Eine verlässliche Funktion ist in einem Temperaturbereich von –40°C bis +105°C gewährleistet.

Interessant ist der Einsatz überall dort, wo ein kompaktes Design gefordert ist: Beispielsweise in der Industrie-Elektronik, im Maschinen- und Anlagenbau sowie in industriellen Mess- und Steuersystemen.

Muster und Datenblätter sind auf Anfrage erhältlich.

Namensgeber der D-Subminiatur-Steckverbinder (abgekürzt D-Sub), ist ihre an den Buchstaben "D" erinnernde Bauform. Die mehrpoligen Steckverbinder wurden 1952 ursprünglich für die Datenübertragung entwickelt.

Robuste Schnittstelle

Als Schnittstellenkomponenten sorgen D-Sub Steckverbinder für eine reibungslose Datenübertragung von Industrieanwendungen. Sie sind einfach anzuwenden, zuverlässig und robust.

Kompakter D-Sub Verbinder

So komplettiert die Serie 114-6 W+P's Produktpalette um ein Verbinder-Paar speziell für den IDC Flachbandkabel-Bereich. Durch verpresste Maße von etwa 14,20mm ohne Zugentlastung, respektive circa 18,80mm mit Entlastung, sind das attraktive Abmessungen, die immer kleiner werdenden Endgeräten entgegenkommen. Geeignete Flachbandkabel im AWG-Bereich 28, runden das Komplettpaket mit der Serie 3560 ab.

Die Gehäuse werden klassischerweise in Stahl (vernickelt) oder optional in Vollkunststoff angeboten, Isolierkörper sind standardmäßig in schwarz vorgesehen, grau und blau sind auf Wunsch ebenso lieferbar.

Mehrere Befestigungsoptionen

Als Befestigungsmöglichkeiten stehen wahlweise zur Auswahl: Metallblenden mit Durchgangsloch, mit UNC 4-40 oder mit M3 Gewindebolzen, außerdem eine Vollkunststoff-Version mit Durchgangsloch. Die IDC D-Sub Male und Female Verbinder sind in den Polzahlen 09, 15, 25 und 37 erhältlich.

Als Kontaktmaterial steht eine Kupferlegierung mit einer vergoldeten Oberfläche über einer Nickelsperrschicht zur Verfügung. Der Durchgangswiderstand beträgt weniger als 20 m, der Nennstrom 1 A, bei einer maximalen Stromtragfähigkeit bis 3 A. Eine sichere Funktion ist in einem Temperaturbereich von –55°C bis +105°C gewährleistet.

Muster und Datenblätter sind auf Anfrage erhältlich.

Neuer Stecker mit spezieller Schirmanbindung

- Entwickelt für dicke Kabeldurchmesser von 6,5 mm bis 8,0 mm

- Austauschbare Aderkämme für verschiedene Aderdurchmesser:

- 1,35 mm, für Aderdurchmesser von 1,24 mm bis 1,34 mm

- 1,45 mm, für Aderdurchmesser von 1,34 mm bis 1,44 mm

- Knickschutztüllen für verschiedene Kabeldurchmesser:

- 8,0 mm, 7,5 mm, 7,0 mm, 6,5 mm

- Vorteile im Vergleich zu ähnlichen Produkten:

- Patentiertes Design des Aufbaus

- Einfaches effizientes und zeitsparendes Konfektionieren

- Erfüllt Standard für CAT6A und im Link CAT8

Neuer ungeschirmter Stecker mit durchgehender Aderführung

- Für dicke Kabel entwickelt

- Lochdurchmesser 1,2 mm bis 1,25 mmfür Einzelader-Durchmesser (inkl. Isolation) von 0,99 mm to 1,19 mm

- Kein Aderhalter, durchgängige Aderführung mit extrem kurzen Löchern

- Minimale Beschädigung der Ader

- Erfüllt Standard CAT6A

Neuer CAT8 Premium Stecker

- Entwickelt für große Kabeldurchmesser von 6,0 mm bis 7,5 mm

- Erreicht im Test CAT8

Neuer Stecker zum Umspritzen

- Austauschbare Aderkämme, mit folgenden Lochdurchmessern:

- 1,10 mm

- 1,05 mm

- 0,95 mm

- 0,90 mm

- Schützt die Adern vor Beschädigung durch hohe Temperaturen beim Umspritzen

- Erreicht im Test CAT6A

Neue Knickschutztülle zum Nachrüsten

- Die Konstruktion besteht aus 2 Tüllenhälften, die einfach über dem Kabel zusammengeklappt werden, ermöglicht die nachträglichen Anbringung einer Knickschutztülle.

- Schützt die Rastnase und erhöht ihre Lebensdauer

- Hochfestes Material zum Schutz

Neuer Stecker aus Nylon

- Rastnase bricht nicht

- Aktuell für Aderdurchmesser von 0,81 mm, Entwicklung für weitere Aderdurchmesser auf Anfrage.

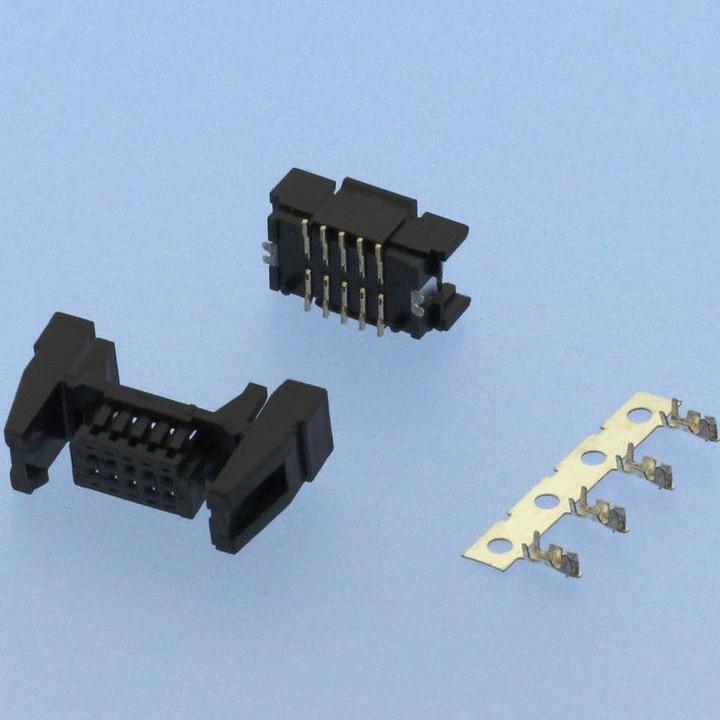

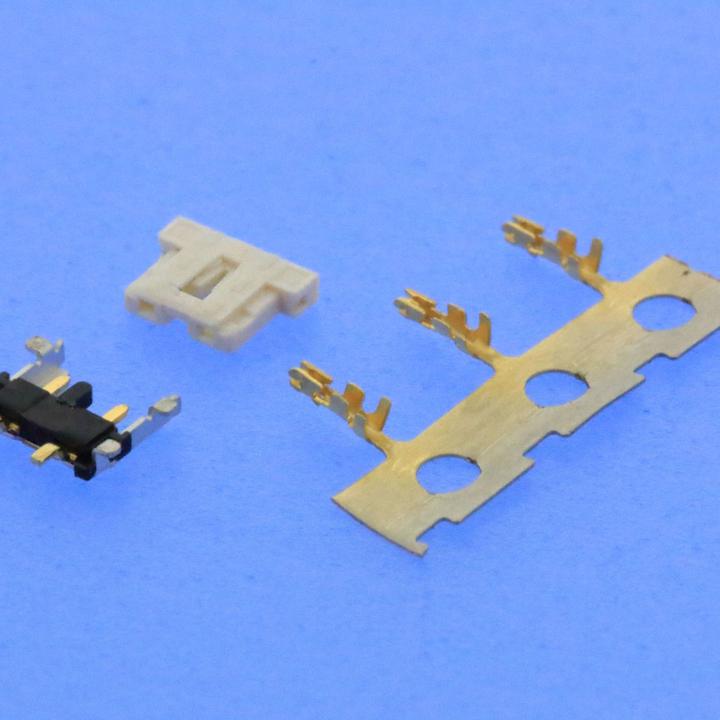

Flexibilität auf kleinstem Raum

In elektronischen Einheiten ist jeder Millimeter kostbar, denn auf kleinstem Raum muss ein kompaktes Innenleben funktionsfähig untergebracht werden. Genau für diese limitierten Platzverhältnisse liefert W+P die intelligente Antwort.

Variable Leiterplattenausrichtung

Kompakt, flexibel und zuverlässig sind die Attribute der Board-to-Board Verbinderserien 9025 und 9026 im Raster 1,27mm. Sie stellen eine Erweiterung des W+P Portfolios an Leiterplatten-zu-Leiterplatten Schnittstellen dar, die dem wachsenden Bedarf an geringen Polzahlen mit kleinen Rastermaßen gerecht werden. Idealerweise sind die beiden einreihigen Serien schon ab einer Polzahl von 02 Kontakten lieferbar, bis zu 12 Kontakte sind maximal möglich.

Eine variable Leiterplattenausrichtung ist ein weiterer Vorteil der stehend und liegenden verfügbaren Steckverbinder, so ergeben sich vielfältige Möglichkeiten, Platinen vertikal, horizontal oder rechtwinkelig miteinander zu kombinieren.

Solide Befestigung auf der Leiterplatte

Das integrierte Gehäuse-Verriegelungssystem der Buchsenleiste gewährleistet einen sicheren Anschluss mit gleichzeitigem Verpolschutz, den Führungskanten im Innenteil zusätzlich unterstützen. Seitliche Lötwinkel übernehmen die Aufgabe einer soliden Befestigung von Stift- und Buchse auf der Leiterkarte.

Kontaktstifte sowie die doppelseitigen Federkontakte der Buchse sind selektiv vergoldet, einsetzbar sind diese bis zu einem Nennstrom von maximal 5 A.

Spezielle Positionierhilfen erleichtern die Ausrichtung auf eine definierte Stelle auf der Leiterplatte. Außerdem stellen Tape-and-Reel-Verpackungen und das optionale Pick-and-Place-Pad (Serie 9025) die ökonomisch automatisierte Bestückung im SMT-Fertigungsprozess sicher. Die Isolierkörper bestehen aus thermoplastischem Kunststoff gemäß UL94 V-0. Im Temperaturbereich von -55°C bis +125°C ist eine zuverlässige Funktion garantiert.

Optimale Einsatzgebiete sind Verbindungen von Leiterplatten und Anschlüsse interner sowie externer Geräte. Zu finden beispielsweise in der Automatisierungstechnik im Embedded Computing Bereich und in industriellen Anwendungen.

Muster der Serien sind auf Anfrage kostenlos erhältlich, Datenblätter stehen auf der Homepage zum Download bereit.

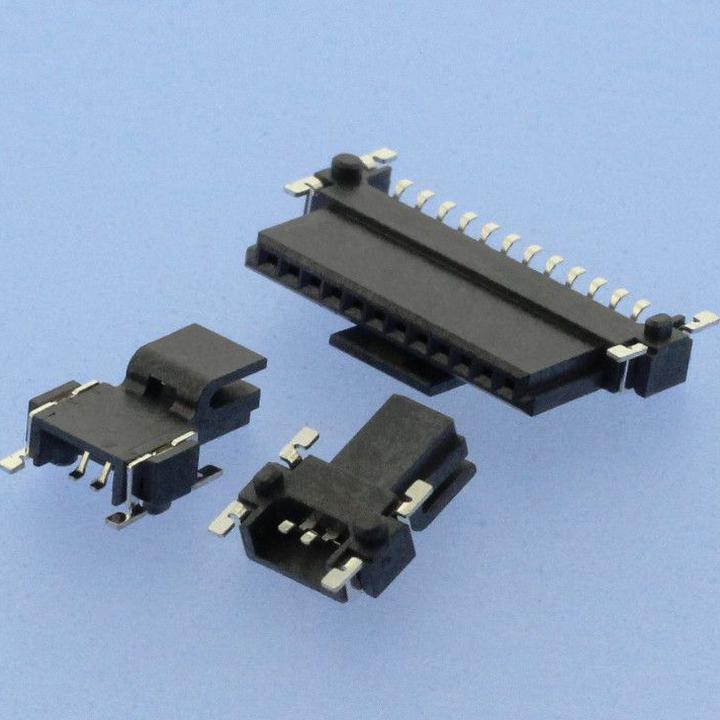

SMT (Surface Mount Technology), THR (Through Hole Reflow) oder beides vereint? Alle Vorteile beider Technologien verbindet die Serie 9231 Typ D.

Der Vibration standhalten

Nützlich ist diese Kombination, wenn es um Stabilität auf kleinem Raum geht. So stellt die THR-Methode, dank ihrer durchsteck-montierten Kontakte, eine belastbare und vibrationssichere Verbindung dar. Oberflächenmontierte SMT Pins kommen ohne zusätzliche Bohrung auf der Platine aus, diese eingesparte Fläche steht somit Leiterbahnen zur Verfügung.

Funktionelle Eigenschaften

Eine Reihe der zweireihigen Stiftleiste ist mit THR-Pins bestückt, die zweite mit SMT-Kontakten. Die Serie 9231 wird liegend im Raster 2,54mm angeboten. Der Nennstrom beträgt 3 A pro Pin, als Kontaktmaterial steht eine Kupferlegierung mit den Oberflächenoptionen vergoldet, verzinnt oder selektiv vergoldet zur Auswahl.

Der Isolierkörper besteht aus thermoplastischem Kunststoff gemäß UL94 V-0, im Temperaturbereich von – 40°C bis +125°C ist eine sichere Funktion gewährleistet. Für den automatisierten Verarbeitungsprozess sind die Verbinder in Stangen mit oder ohne Pick-and-Place-Pad erhältlich, wahlweise gegurtet als Tape&Reel Variante.

Platzsparend und stabil

THR-SMT Mixed Kombinationen werden überall dort eingesetzt, wo die Leiterplatten-Architektur belastbare und gleichzeitig raumsparende Bauteile benötigt.

W+P bietet passende Gegenstecker sowie weitere Mixed-Technology-Steckverbinder an, ebenso stehen Datenblätter und Muster bereit.

Steckverbindergehäuse erfüllen im Wesentlichen zwei Funktionen: Sie stellen eine verlässliche Verbindung von Stecker und Gegenstück sicher und schützen diese samt Innenleben vor mechanischen-, elektrischen- und thermischen Einflüssen.

Echtes Multitalent

Gehäuse können noch mehr - dank ihrer kodierten Formgebung gewährleisten sie eine Verpolsicherheit, optionale Zugentlastungen fangen z.B. hohe Kräfte zum Schutz der Kabel ab. Zudem bieten Gehäuse-Verriegelungen Bauteilen einen soliden Halt gegen unbeabsichtigtes Trennen - so sorgen die unterschiedlichsten Arten mit ihren ineinandergreifenden, mechanischen Vorrichtungen für zuverlässige Befestigungen. Zur Verfügung stehen hierbei Rasthaken, Klappverriegelungen, Hebelsysteme, Verschraubungen oder Bajonettverschlüsse.

Platzsparendes Rastermaß

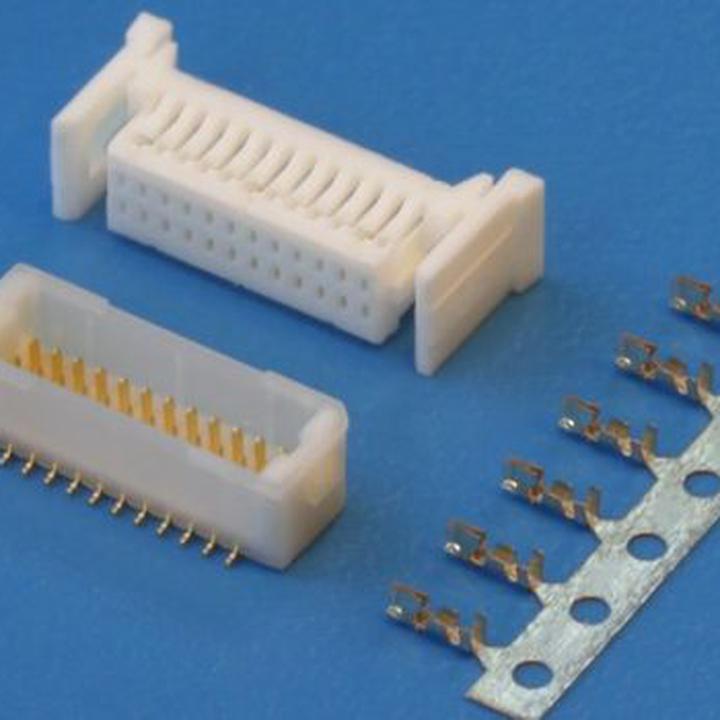

Mit der SMT-Crimp-Rast Serie 1251 präsentiert W+P ein weiteres Produkt mit Verriegelungsmöglichkeit aus dem W-t-B Umfeld: Rasthaken am Buchsengehäuse übernehmen hier die Aufgabe der Sicherung, komplettiert wird das System durch Buchsenkontakte und Wannenstiftleisten.

Das Rastermaß beträgt platzsparende 1,25mm. Es sind 10, 20, 30 und 40 Kontakte erhältlich, die in zweireihiger, vertikaler Ausführung verfügbar sind. Der akzeptierte Leiterquerschnitt ist mit AWG 32 – 26 angegeben.

Der Isolierkörper besteht aus thermoplastischem Kunststoff gemäß UL94 V-0. Eine zuverlässige Funktion ist in einem Temperaturbereich von -25° C bis +85° C gegeben, die Verarbeitung erfolgt im Reflowlötverfahren.

Kostenlose Muster und Datenblätter sind auf Anfrage erhältlich.

Werden hochwertige, zuverlässige und kurzfristig umsetzbare Kabelkonfektionen gebraucht, steht ein Komplettanbieter mit einem breiten Spektrum an Technologievielfalt bereit.

Neben verlässlichen Standard-Lösungen sind es insbesondere maßgeschneiderte Projekte, bei denen W+P ihr umfangreiches Know-how unter Beweis stellt.

Hierbei kommen UL-zertifizierte Litzen und Kabel, Flexkabel sowie Flachbandkabel zum Einsatz. Die Kabeltypen können mit diversen Anschlusstechniken individuell assembliert werden, unter anderem mittels IDC, Crimp- oder Lötanschluss. Auch eine Kombination unterschiedlicher Steckverbinderfamilien an einem Kabel ist möglich.

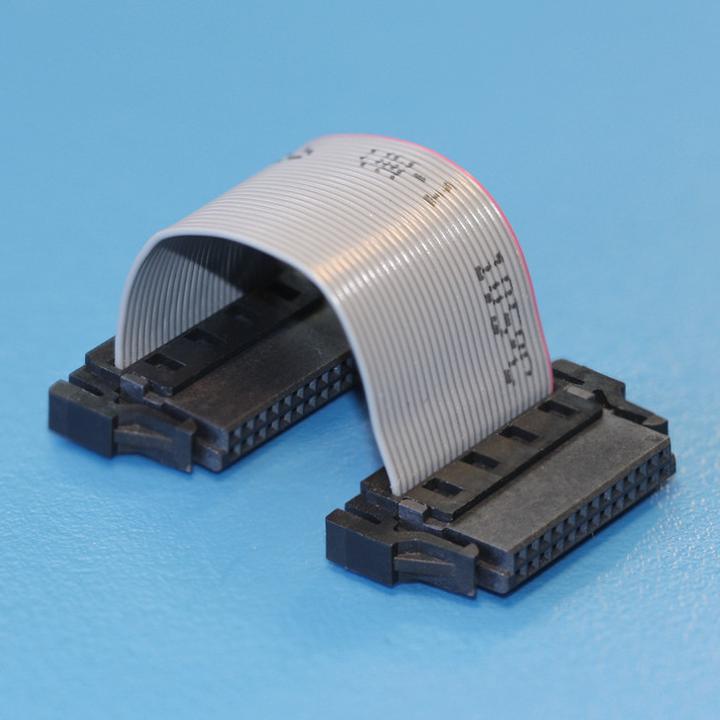

Mit der Serie 998-916 erweitert W+P das Portfolio als Version mit IDC Anschluss-Technik im Raster 1,27mm, sie ist beidseitig konfektioniert erhältlich. Vier verschiedene Ausrichtungen des Steckgesichtes sind möglich. Des Weiteren ist die Länge des Flachbandkabels anwendungsgerecht frei wählbar, bei einem Aderquerschnitt von AWG 30.

Die zweireihige Schneid-Klemm-Buchse ist in etlichen Polzahlen lieferbar. Die Isolierkörper bestehen aus Thermoplast gemäß UL94 V-0, im Temperaturbereich von -20° C bis +105° C ist eine zuverlässige Funktion garantiert.

Optimale Einsatzgebiete sind Verbindungen von Leiterplatten und Anschlüsse interner sowie externer Geräte, die mechanischen Belastungen standhalten müssen. Zu finden beispielsweise im Embedded Computing Bereich, Automatisierungstechnik und in industriellen Anwendungen.

Datenblätter und Muster sind kostenlos erhältlich.

Steckverbinder sind die am wenigsten wahrgenommenen Teile eines Endproduktes. Größtenteils auf einer Leiterplatte verbaut, sind diese meist bis auf den externen Anschluss zur Energiequelle unsichtbar, dabei werden sie oft unterschätzt. Ein elektronisches Gerät ohne Steckverbinder? Undenkbar!

Ganz entgegen des Trends immer kleiner werdender Rastermaße und Bauhöhen, bietet W+P einen Riesen im Raster 9,0mm an. Auch er hat seine Abnehmer, in diesem Fall sind es Produkte aus dem Embedded Computing Bereich sowie die allgemeine Stromversorgung von Peripheriegeräten. Diese Art von Kabel-zu-Kabel (Wire-to-Wire) Verbindung in Crimptechnik wird in schwer zugänglichen Einsatzgebieten verwendet, die eine Stromversorgung mit hohen Strömen fordern.

Das mechanisch kodierte Gehäusedesign von Stift- und Buchse der Serie 991 lässt einen verriegelbaren Anschluss zu, indem sich die mittige Rastnase des Stiftgehäuses hörbar mit dem Buchsengehäuse zusammenfügt. So wird versehentliches Lösen verhindert, gleichzeitig dient diese Sicherungsart als Verpolschutz.

Zugehörige Stift- und Buchsenkontakte gestatten eine hängende und lösbare Schnittstelle, robuste Crimpverbindungen dieses Typus gewährleisten hohe elektrische sowie mechanische Zuverlässigkeit, gefordert etwa im erschütterungs- und vibrationsreichen Umfeld.

Die Serie 991 ist in folgenden Kontaktzahlen erhältlich: 02, 03, 04 und 06, anwendbar auf einem Kabelquerschnitt von AWG 20 – 14, sind die Steckverbinder für bis zu 15 A pro Kontakt einsetzbar. Als Kontaktmaterial steht eine Kupferlegierung mit einer verzinnten Kontaktoberfläche zur Verfügung, die Isolierkörper bestehen aus thermoplastischem Kunststoff gemäß UL94 V-2. Im Temperaturbereich von -25°C bis +85°C ist eine zuverlässige Funktion garantiert.

Interessante Einsatzgebiete stellen schwer zugängliche Bereiche dar, die eine mechanisch belastbare, aber gleichzeitig schwimmend befestigte Stromversorgung erfordern. Muster und Datenblätter der Serie 991 sind auf Anfrage kostenlos erhältlich.

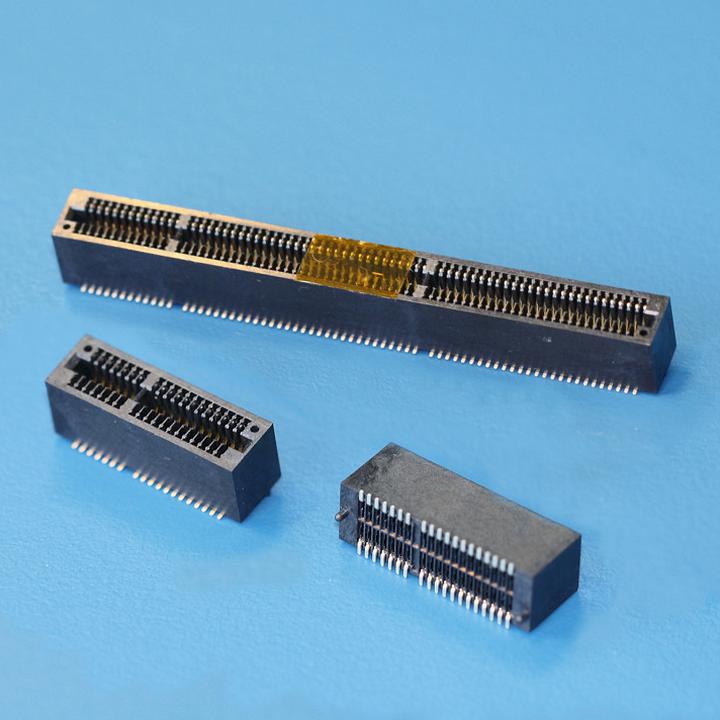

Die Produktbezeichnung "Card-Edge" beschreibt bereits Funktion und Kontaktbereich des Bauteils.

So erfolgt die Kontaktierung eines weiteren Boards ohne Umwege am Platinenrand: Ein zusätzlicher Steckverbinder entfällt, das schafft Platz auf der Leiterkarte und verringert den Bestückungsaufwand.

Mit einem Rastermaß von 1,00mm ist das Design der Serie 1282 bestens für Raumsparlösungen in den Bereichen Telekommunikations- und Industrietechnik geeignet.

10 bis 140 Kontaktpositionen mit unterschiedlicher Kodierung bieten die oberflächenmontierbaren Bauteile, wobei weitere Kodierungen auf Anfrage möglich sind. Die direkte Kontaktierung zu einem weiteren Board erfolgt im Slot mittels beidseitiger Kontaktfedern.

Anwendbar sind W+Ps Platinenrandverbinder bis zu einer Leiterplattendicke von 1,60 mm (+/- 0,16 mm). Die Höhe des Nennstroms beträgt 1,1 A, im Kontaktbereich ist der Verbinder vergoldet, im Lötbereich steht eine verzinnte Oberfläche zur Verfügung.

Eine automatische Bestückung mit Verarbeitung im SMT-Fertigungsprozess ermöglicht die gegurtete (Tape & Reel) Lieferform, auf Wunsch mit Film-Pad. Der Isolierkörper besteht aus thermoplastischem Kunststoff gemäß UL94 V-0. Im Temperaturbereich von -55°C bis +105°C ist eine sichere Funktion garantiert, der Lötvorgang erfolgt im Reflow-Verfahren.

Kostenlose Muster sind auf Anfrage erhältlich.

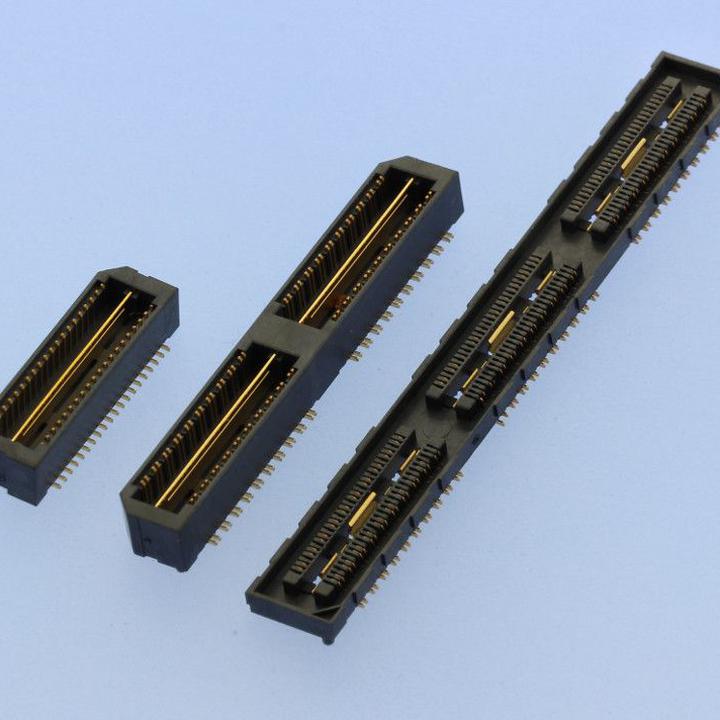

Überall dort, wo kompaktes Stapeln von Leiterplatten in limitierten Platzverhältnissen gefordert wird, kommen sie zum Einsatz. Die Rede ist von B-t-B (Board-to-Board) Steckverbindern, die dank ihrer niedrigen Bauhöhe einen minimalen Leiterplattenabstand garantieren. Da trendgemäß nahezu proportional zur schrumpfenden Gehäusegröße die Datenrate steigt, bieten W+P`s neue B-t-B Verbinder auch hier eine optimale Lösung:

Designed sind die SMT Serien für moderne und anspruchsvolle Highspeed Applikationen mit bis zu 28 Gbps, beispielsweise im Embedded Computing oder Industrieanwendungen. Im Einzelnen: Serie 5055, mit einer maximalen Performance von 25 GB/s, bei der Serie 5088 sind es wahlweise 14 GB/s vollbestückt, bzw. 28 GB/s als paarweise bestückte Version, hier kann die Übertragung der hohen Frequenzen differenziell erfolgen. Wobei die differentielle Übertragung durch die paarweise Verteilung der Pins weit weniger störempfindlich ist, da die gekoppelten Pins jeweils ein Signal mit entgegengesetzter Polarität zeitgleich aussenden.

Die in vertikaler Ausrichtung gestalteten Verbinder weisen eine Bauhöhe von 2,05 mm (Female) und 4,27 mm (male) auf, daraus ergibt sich ein Leiterplattenabstand von 5 mm. Zusätzlich ermöglicht die dichte Kontaktgestaltung im Raster 0,5 mm (5055) / 0,8 mm (5088) Entwicklern platzsparende Konstruktionen, bei denen geräteinternes Stapeln von Leiterplatten verlangt wird.

Ausgelegt als Wannenstecker steckseitig, gestattet die spezielle Gehäusegeometrie der B-t-B Komponenten verpolsicheres Kontaktieren. Hierbei erfolgt die Masseversorgung über eine zentrierte, elektrisch leitende Oberfläche im male-Kontaktbereich und durch Federkontakte Buchsen-seitig.

Als voll bestückte Version sind die zweireihigen Steckverbinder mit 60, 120, 180 (5055) und 40, 80, 120 (5088) Kontakten lieferbar, die paarweise bestückte Ausführung sieht folgende Unterscheidung vor: 5055 – 40, 80 und 120 Kontakte, 5088 – 28, 56 und 84 Kontakte.

Positionierhilfen übernehmen die Aufgabe des fehlerfreien Ausrichtens an eine definierte Stelle auf der Leiterplatte. Ohne Stabilitätsverlust sind beide Serien für mindestens 100 mechanische Steckzyklen geeignet. Einsetzbar sind die Kontakte bis zu einem Nennstrom von bis zu 2 A, abhängig von der Belegung, bei der Ground Plane sind es 7,8 A.

Eine vollautomatische Bestückung mit Verarbeitung im SMT Fertigungsprozess ermöglicht die gegurtete Lieferform mit Film Pad. Der Isolierkörper besteht aus thermoplastischem Kunststoff gemäß UL94 V-0. Im Temperaturbereich von -55°C bis +125°C ist eine sichere Funktion garantiert.

Datenblätter sind als Download erhältlich, entsprechende Muster können kostenlos angefordert werden.

Mit den W-t-B IDC Serien 601 und 602 präsentiert W+P eine Möglichkeit, auch größere Kabel-Querschnitte zu verarbeiten. So wird ein schneller Anschluss von Leitungen realisierbar. Die Steckverbinder selber können auch mittels Handwerkzeug einfach im Feld installiert werden.

Ausgelegt ist der Schneid-Klemm-Bereich der Serie 601 auf einen Leiterquerschnitt von AWG 28 - 22, das Rastermaß beträgt 2,54mm. Bei der Serie 602 liegt der Leiterquerschnitt bei AWG 24 – 18, mit einem Rastermaß von 3,96mm.

Die Buchsen der beiden Serien sind als Durchgangs-, bzw. Endoption, mit oder ohne Kodierung (nur 601) erhältlich. Bei den Stiftleisten besteht die Wahlmöglichkeit zwischen einer geraden und gewinkelten Version, die mit einer zusätzlichen Rastoption angeboten werden. Zudem erhältliche Schutzkappen sorgen für eine sichere Verbindung, die bei den Buchsen eine Zugentlastung ermöglicht. Datenblätter geben übersichtlich und detailliert Auskunft der einzelnen Bestellalternativen. W+P bietet hiermit ein vielfältiges System an, das etablierte, schon am Markt befindliche Produkte ersetzen kann.

Als Kontaktmaterial steht eine Kupferlegierung bereit, bei Nennstrom und Nennspannung unterscheiden sich die Serien: 3 A und 250 V AC sind es bei der Serie 601, 5 A und 600 V AC bei der Serie 602. Die Anzahl der Kontakte reicht von 02 – 16 (Serie 601) und von 02 – 20 (Serie 602), eine Ausnahme bilden die Stiftleisten der Serie 601, diese sind sogar bis 40-polig lieferbar.

Das Isolierkörpermaterial bestehen aus thermoplastischem Kunststoff gemäß UL94 V-2 und UL94 V-0. Eine sichere Funktion ist in einem Temperaturbereich von -25° C bis +85° C gegeben, die Verarbeitung erfolgt im Wellenlötverfahren. Kostenlose Muster und Datenblätter sind ebenfalls erhältlich. Ein ideales Einsatzgebiet ist die Herstellung von Stromversorgungsleitungen.

Geht es um hochwertige, zuverlässige und kurzfristig umsetzbare Kabelkonfektionen, unterstützt Sie W+P als zertifizierter Komplettanbieter mit einem breiten Spektrum an Technologievielfalt. Neben verlässlichen Standard-Kabelkonfektionen sind es insbesondere maßgeschneiderte Lösungen, bei denen W+P sein Know-how unter Beweis stellen kann. Das zugehörige Foto zeigt eine USB Typ C Kabelkonfektion zu allen USB Typen.

Zum Einsatz kommen dabei UL-zertifizierte Litzen und Kabel, Flexkabel sowie Flachbandkabel. Die Kabeltypen können mit den unterschiedlichsten Anschlusstechniken individuell konfektioniert werden, unter anderem mittels Crimp-, IDC oder Lötanschluss. Auch eine Kombination unterschiedlicher Steckverbinderfamilien an einem Kabel ist möglich.

Vorkonfektionierte Lösungen, wie beispielsweise USB, RJ45 oder D-Sub, sind in vielfältigen Längen, Rastermaßen, Kontaktzahlen, Ausrichtungen etc. erhältlich.

Beim Entwicklungsprozess sieht sich W+P als professioneller Partner, der während des gesamten Projektablaufs mit qualifizierter Betreuung zur Seite steht. Wobei besonders die Erfüllung aller Bedürfnisse kundenseitig zählt, die technologische und wirtschaftliche Machbarkeit aber im Auge behalten wird.

Neben einer kompetenten Beratung samt Anforderungsanalyse, spielt die passgenaue, auf die jeweilige Applikation abgestimmte Entwicklung eine große Rolle. Sie wird begleitet von Zeichnungen und Prototypen, bis zur letztendlichen Prüfung und Auslieferung des Produkts mit Serienreife.

Ziel ist, stets mit einem bestmöglichen Preis-Leistungs-Verhältnis auf einem hohen technischen Niveau zu punkten. Unserer Meinung nach ist Qualität das überzeugendste Argument.

W+P erweitert sein etabliertes Board-to-Board (B-t-B) Programm um fünf Serien, bestehend aus vier Steckverbinder-Serien und eine Kabelkonfektion in Schneidklemmtechnik. Während die Serien 9017 bis 9020 unter anderem flexibles Anordnen von Leiterplatten gestatten, ermöglicht die vorkonfektionierte Serie 998-916 einen sicheren Anschluss, der auch mechanischen Belastungen standhält.

So bieten die SMT Stift- und Buchsenleisten der Serien 9017 bis 9020 vielfältige Kombinationsmöglichkeiten von Leiterplatten: Vertikales und horizontales Verbinden von Platinen, ebenso ist ein Mix aus einer stehenden und liegenden Variante möglich, die eine rechtwinkelige Anordnung erzeugt. Zusätzliche seitliche Lötwinkel sorgen für eine solide Befestigung auf der Leiterkarte.

Insgesamt stehen 10 verschiedene Polzahlen zwischen 12 und 80 Kontakten zur Verfügung. Als Kontaktmaterial wird eine Kupferlegierung mit den Oberflächenoptionen von Flash vergoldet bis zu einer Beschichtung von 0,75 µm Gold angeboten. Die Isolierkörper bestehen aus thermoplastischem Kunststoff gemäß UL94 V-0. Eine sichere Funktion ist in einem Temperaturbereich von -55° C bis +125° C gegeben.

Mit der Kabelkonfektions-Serie 998-916 erweitert W+P das Portfolio als Version mit IDC Anschluss-Technik, sie ist beidseitig konfektioniert erhältlich. Vier verschiedene Ausrichtungen des Steckgesichtes sind möglich, des Weiteren ist die Länge des Flachbandkabels anwendungsgerecht frei wählbar, hier liegt der Aderquerschnitt bei AWG 30. Passend zu den oben genannte B-t-B Serien ist die zweireihige Schneid-Klemm-Buchse gleichfalls in 10 verschiedenen Polzahlen lieferbar. Als Kontaktmaterial steht eine Kupferlegierung mit einer Gold-Oberfläche von 0,75 µm zur Verfügung. Hier wird der Isolierkörper aus hochtemperaturbeständigem Kunststoff gemäß UL94 V-0 angeboten, der geeignete Temperaturbereich reicht von -20° C bis +105° C.

Optimale Einsatzgebiete sind Verbindungen von Leiterplatten und Anschlüsse interner sowie externer Geräte. Zu finden beispielsweise im Embedded Computing Bereich, Automatisierungstechnik und in industriellen Anwendungen.

Datenblätter und entsprechende Muster können kostenlos angefordert werden.

Geht es um den Einsatz nicht-lösbarer Verbindungen auf der Leiterplatte, bieten Crimp-Anschlüsse eine hohe mechanische Stabilität.

W+P bietet eine Reihe von Wire-to-Board Verbindern als Board-In-Lösungen an, die durch das direkte Einlöten in die Leiterplatte eine dauerhafte und zugleich sichere Verbindung herstellen. Zur Stabilisierung auf der Leiterplatte sind alle Kontakte mit einer zusätzlichen Rückhaltefunktion ausgestattet, um die Verarbeitung zu erleichtern.

Als Kontaktmaterial wird für alle Serien eine Kupferlegierung verwendet. Erhältlich sind die Kabel-zu-Leiterplattenkontakte in unterschiedlichen Rasteroptionen: 2mm, 2,50mm und 3,96mm, in gerader und gewinkelter Bauform. Der Aderquerschnitt ist ausgelegt für einen AWG-Bereich von 30 bis 16, je nach Serie. Die Höhe des Nennstroms reicht von 1 A bis zu 7 A, ebenso variiert die Anzahl der Einlötkontakte zwischen 2 und 16. Eine sichere Funktion ist in einem Temperaturbereich von -25°C bis +85°C gewährleistet.

Alle weiteren technischen Daten finden sich in den jeweiligen Datenblättern der Serien: 523, 524, 571, 572, 573 und 593.

Eine Crimp-Einzelkontakt-Serie (600) komplettiert die Board-In Angebotsvielfalt: Als Kontaktmaterial steht hier eine Kupferlegierung mit einer Kontaktoberfläche aus Zinn über Nickel zur Verfügung. Ausgelegt für einen Kabelquerschnitt von AWG 22 – 18, bzw. 28 – 24, ist die Serie einsetzbar für Bohrungsdurchmesser von 1,0 bis 1,2mm (Option 10) und 1,8mm (Option 18). Weitere Infos: wppro.com/serie-600

Typische Einsatzgebiete von Board-In Lösungen finden sich in den Bereichen Industrieelektronik, Beleuchtung und in Stromversorgungen.

Vielfältige Anforderungen, aber zu wenige Lösungenin kleinen Rastermaßen? Das ändert sich mit der SMT Serie 5265 von W+P.

Sie bietet eine Kabel-zu-Leiterplatten Verbindung alsCrimp-Rast System,diesowohl in klassischen W-t-B Anwendungen, alsauch im LED Bereichverwendet werden kann.

Bestehend aus einer liegenden Stiftleiste, Buchsenkontaktenund einem Buchsengehäuse,sorgen die zweipoligen Bauelemente für eine sichere Kontaktierungund präzise Verbindung; dank des geringen Rastermaßes von 1,80mm und der niedrigen Bauhöhe von 0,9mm,bietet die Serie ein optimal-kompaktes Platzergebnis.

Das System deckt Aderquerschnitte von AWG 34 –28ab. Eine Stromtragfähigkeit bis zu 2 A ist gegeben, im Einzelnen: (1,3 A AC/DC –AWG 34, 1,5 A –AWG 32, 1,8 A –AWG 30, 2,0 A –AWG 28).

Das Kontaktmaterial besteht aus einer Kupferlegierung, der Isolierkörper aus thermoplastischem Kunststoff gemäß UL94 V-0. Ausgelegt ist die Serie 5265 für einen Durchgangswiderstand von <20mΩ, im Temperaturbereich von -25°C bis +85°C ist eine sichere Funktiongarantiert. Die Verarbeitung erfolgt im Reflow-Lötprozess.

Auch diese oberflächenmontierbare Serie passt zu den gängigen Design-Anforderungen der Miniaturisierung. Anwendungen sind neben dem industriellen Sektor, wie beispielsweise Sensoren und Stromversorgungen im Embedded Bereich, Industrieelektronik, Meß-und Regeltechnik, Steuerungstechnik, auch LED Applikationen.

Datenblätter und entsprechende Muster können kostenlos angefordert werden.

Ohne die passenden Komponenten wäre eine Platine bloß ein lebloser Träger elektronischer Bauteile mit Leiterbahnen. Neben anderen notwendigen Elementen schaffen es erst Steckverbindersysteme, einer Leiterplatte Leben einzuhauchen.

Oft verwendete Komponenten sind beispielsweise Wire-to-Board / Wire-to-Wire Anschlüsse, die als wesentliche Funktion eine Verbindung zwischen zwei Kabeln oder eines Kabels mit der Platine realisieren, um so die Strom- und Signalversorgung zu garantieren.

W+P sichert mit fünf neuen Artikelserien: 499, 570, 589, 5113 und 5265 den Bedarf an besonders kleinen Rastermaßen der Crimp-Rast W-t-W / W-t-B Produktfamilie. Die Serien werden als Stift- (PCB/Kabel) und Buchsenleisten (Kabel), Buchsengehäuse sowie Kontakte angeboten. Erhältlich sind diese ab einem Rastermaß von nur 1,0mm, in liegender oder stehender Ausrichtung, teilweise mit Verriegelung.

Das Kontaktmaterial besteht aus einer Kupferlegierung, die Isolierkörper aus thermoplastischem Kunststoff gemäß UL94 V-0. Angeboten werden die genannten Bauteile in unterschiedlichen Veredelungen, ausgelegt für einen Kabelquerschnitt von zusammengefasst AWG 34 - 22. Die Anzahl der Kontakte variiert zwischen 2 und 50. Entsprechende Datenblätter stehen zum Download bereit.

Interessante Einsatzgebiete der platzsparenden und sicheren Wire-to-Board und Wire-to-Wire Systeme sind der Transport von Strom und Signalen in Bereichen wie Embedded, Industrieelektronik, Beleuchtung oder Meß- und Regeltechnik.

Auf Wunsch entwickelt und fertigt W+P kundenspezifische Lösungen. Muster der oben beschriebenen Produkte sind auf Anfrage kostenlos erhältlich.